Hot Products

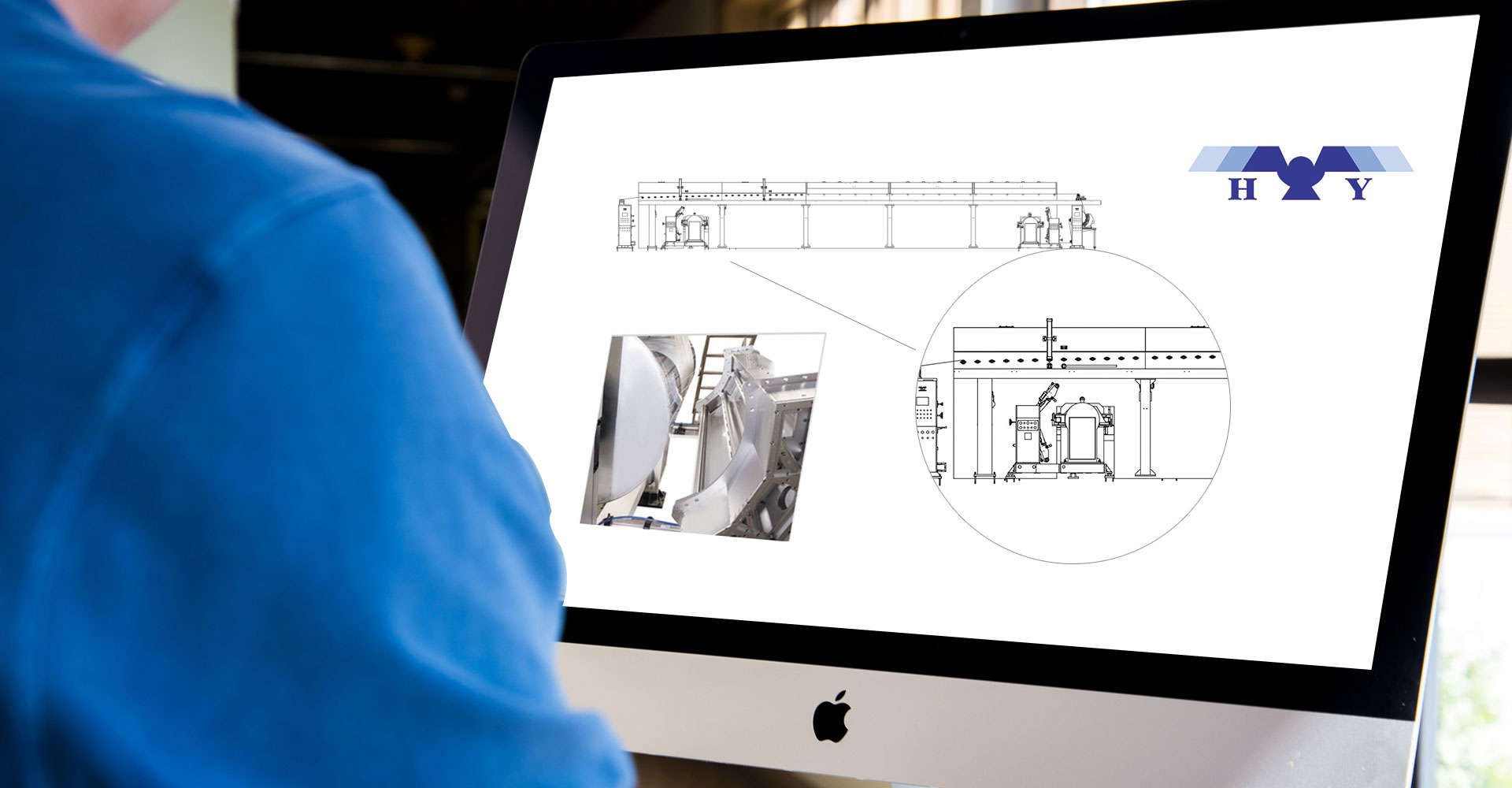

The company currently mainly provides: high-speed solar backplane coating composite equipment, power battery aluminum-plastic composite film coating composite equipment, decorative material printing composite coating online equipment, 5G film coating machine, optical conductive film coating machine, protection Film coating machine, window film coating machine, coating product test center and other major series of coating complete sets of equipment.

About

Shantou Huaying Converting Equipment ltd.was established in 2010. It is located in Shantou Industrial Transfer Park, Haojiang District, Shantou City. It covers an area of 40,000 square meters. It is a national high-tech enterprise specializing in R&D and manufacturing of high-speed precision coating machines in China. . In 2011, the company introduced advanced coating technology from Switzerland to develop domestic leading high-speed coating equipment. The company currently mainly provides: high-speed solar backplane coating composite equipment, power battery aluminum-plastic composite film coating composite equipment, decorative material printing composite coating on-line equipment...

Advantage

Years of technological innovation and the absorption and introduction of foreign advanced coating equipment manufacturing technology, provide customized high-speed precision coating equipment for domestic and foreign customers.

/

01

Innovation

Technology/professional/breaking conventions/security

/

02

Energy saving

Sustainability/saving profit/future outlook

/

03

Practical

Interaction/Ease of Use/Intuitiveness/Humanization/Comfort

/

04

credit

Brand familiarity/respect/reliability/trustworthy/close

2020-12-23

Coating machine maintenance knowledge 2: conveyor belt maintenance

2020-12-23

Maintenance knowledge of coater

2020-12-23

What are the types and characteristics of coater?

2020-12-23

What are the technological requirements and advantages of the coater?

Contact Info

Address: Keyun Road, Industrial Transfer Park, Shantou City, Haojiang District, Shantou City, Guangdong Province

Tel:400-880-6066

Fax:+86-0754-88226282

E-mail:sales@hyspe.com

Mobile website

Copyright © 2021 Shantou Huaying Converting Equipment ltd. 粤ICP备2020125445号 Powered by:www.300.cn

400-880-6066

400-880-6066

Messages

Messages